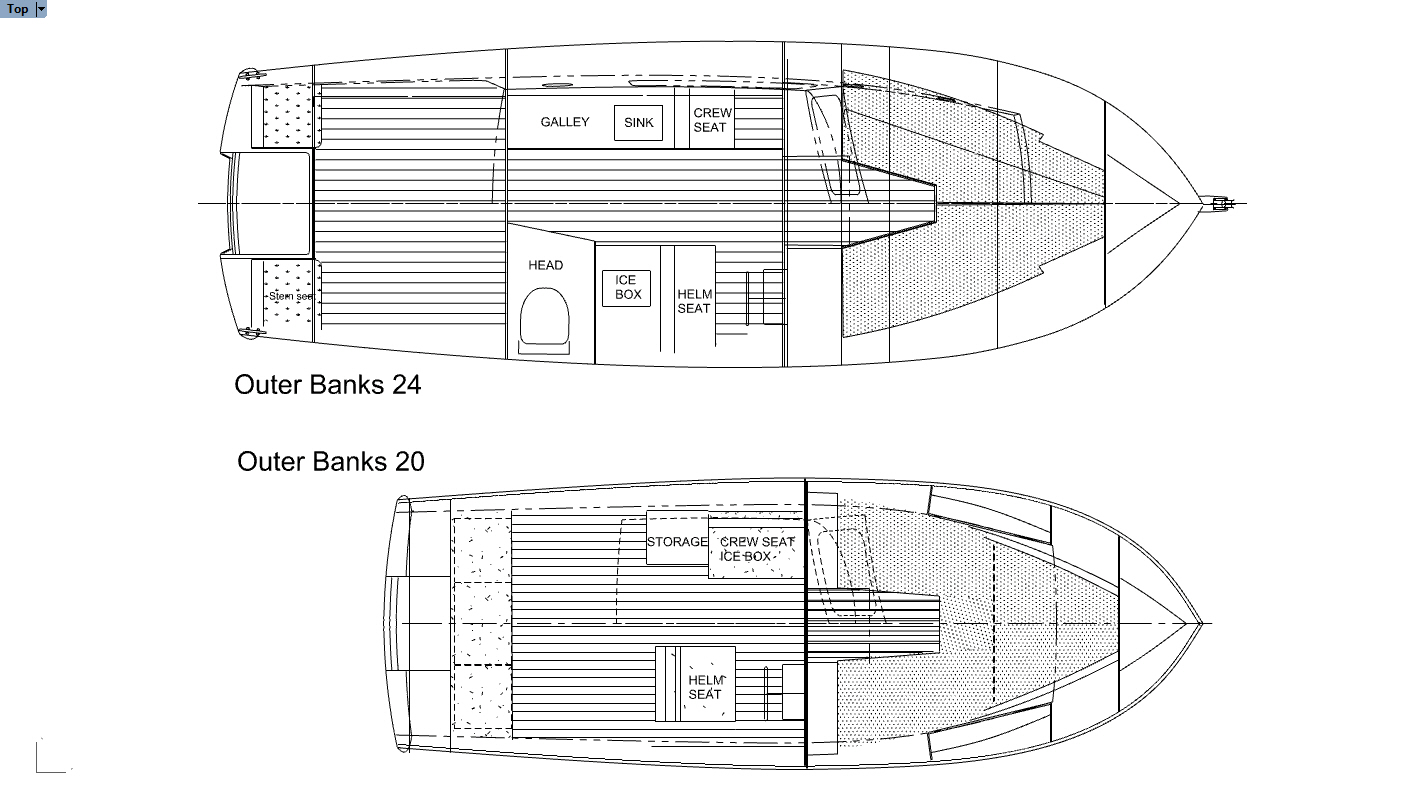

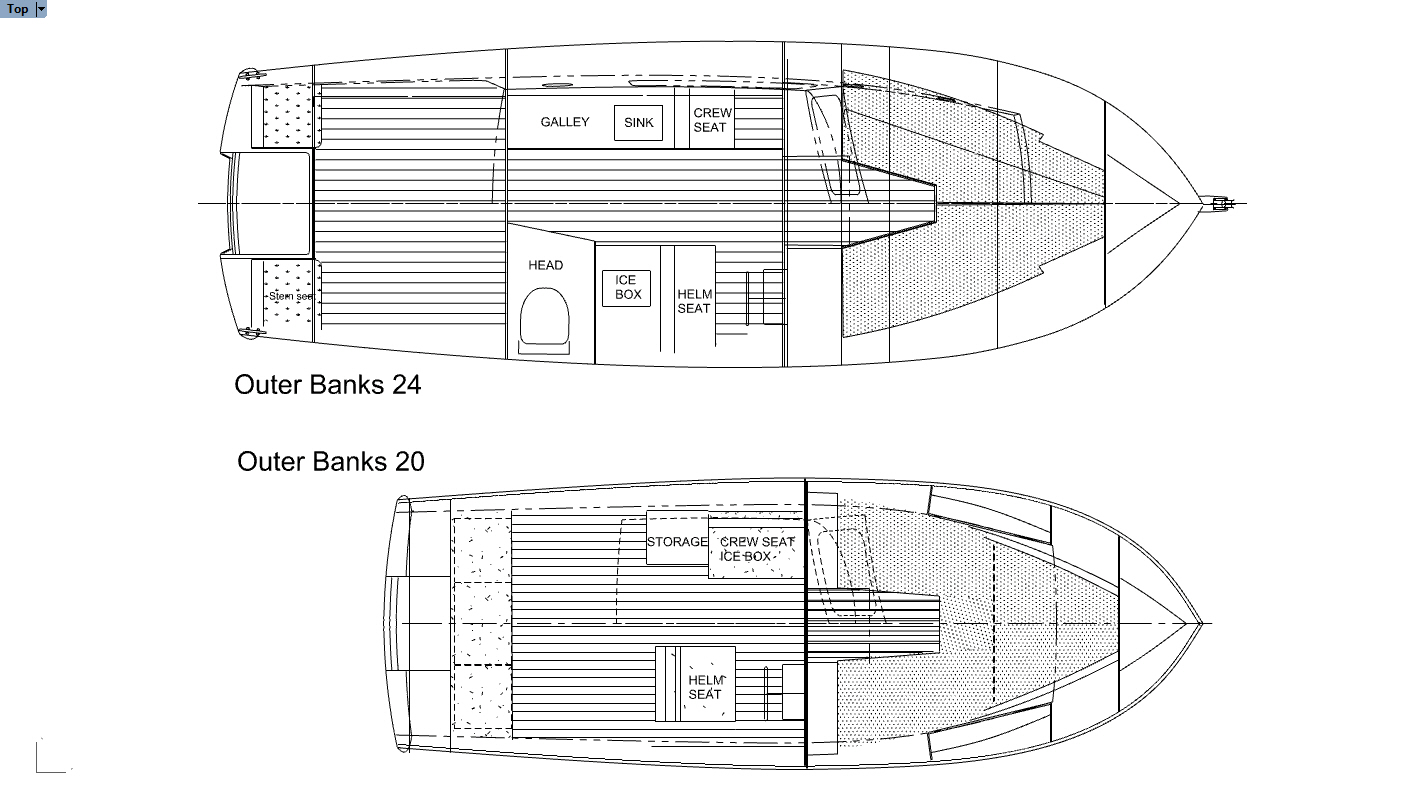

Below: A comparison between the Outer Banks 20 and the 24. Note the Larger enclosed cockpit, head and galley space absent in the OB-20.

Builders Logs Estimated Materials List

The Outer Banks 24 is designed to be an economical cruiser for a couple. She has substantially more living accommodation than her 20′ little sister, the Outer Banks 20 but is also a larger vessel. With 6′ 3″/1.9m standing head room in the pilot house, which is fully enclosed. She is more of a weekend cruiser than the 20 which is predominately a day boat with modest on board living accommodations for overnighting. The Outer Banks 24 has a small galley, and enclosed head.

Her beam is maximized to the widest allowable in the majority of the states, so she can be trailered anywhere (in the USA). Along with her lobster boat-style aesthetics, she retains the sea kindliness and economy that has made the Outer Banks 20 a popular choice. Below, a beautiful Outer banks 24 built in Korea.